T-480 - Tool & Cutter Grinding Machine

T-480 - Tool & Cutter Grinding Machine

Couldn't load pickup availability

T-480 - Tool & Cutter Grinding Machine: Precision, Efficiency, and Longevity in Tool Sharpening

Every toolmaker and machinist understands the frustration of worn-out cutting tools—compromised precision, reduced efficiency, and costly replacements. What if you had a tool and cutter grinding machine that not only revived your tools but did so with unmatched accuracy and ease?

Introducing the T-480 - Tool & Cutter Grinding Machine

Manufactured by APAR India Machines, the T-480 is a product of continuous innovation spanning over three decades. It is the ultimate solution for precise tool sharpening and grinding. Designed for professionals who demand high performance, this machine is widely recognised in both Indian and international markets for its reliability, precision, and user-friendly operation.

The Challenge: Precision Tool Sharpening

Conventional grinding machines often lack accuracy, demand frequent adjustments, and struggle to handle tools with varied geometries. This leads to inefficiencies in operations and frequent tool replacements—adding unnecessary costs and downtime.

The Solution: Why the T-480 Stands Out

-The T-480 - Tool & Cutter Grinding Machine is engineered to overcome these challenges with a suite of advanced features:

-The hardened & thread ground lead screws in the cross & pillar slide ensure micro-feed responsiveness, providing precision sharpening with minimal effort.

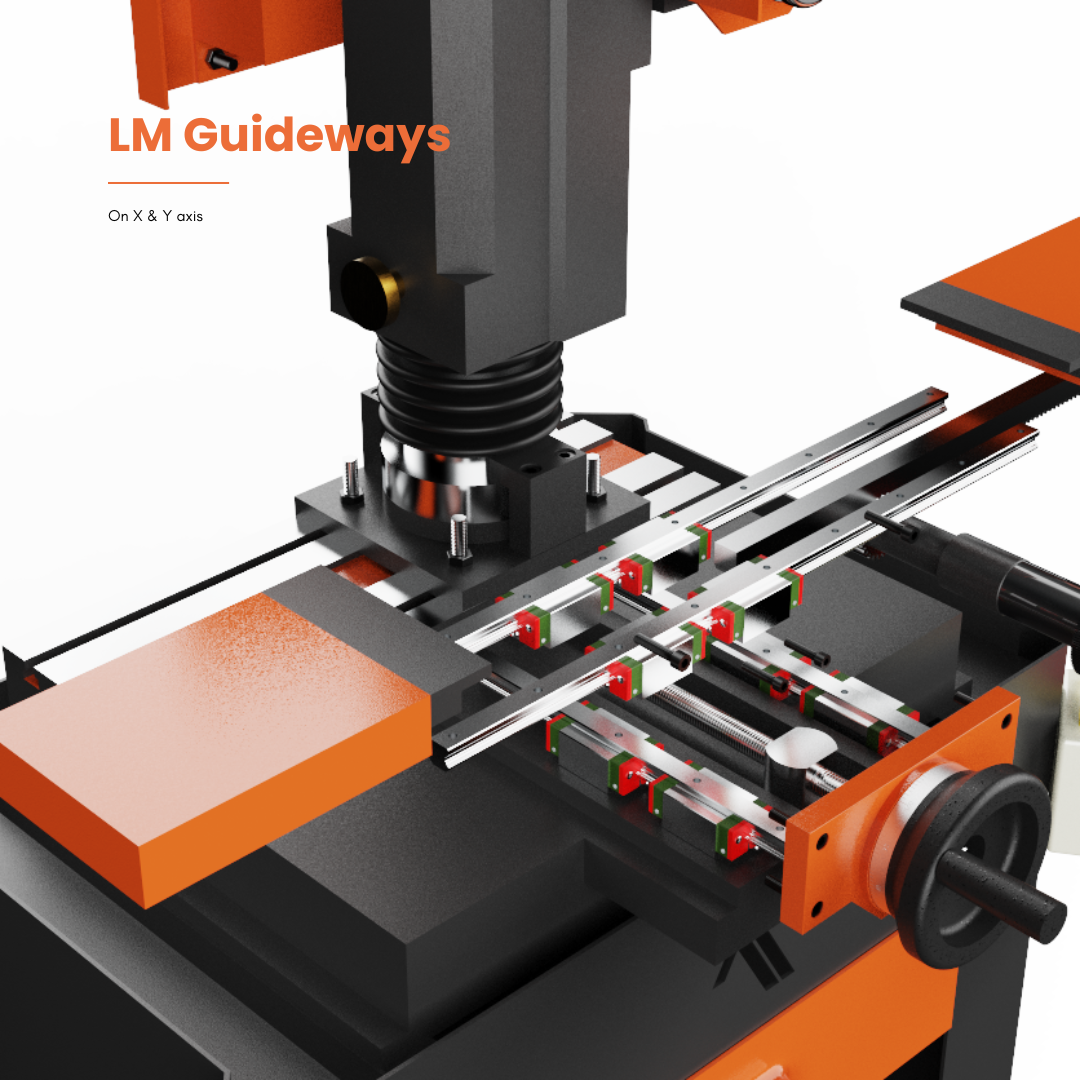

-The worktable slide is equipped with precision linear roller guide ways, enabling smooth, friction-free movement for highly repeatable sharpening.

-A fine-adjustment mechanism ensures guideways are set precisely to match your specific sharpening needs.

-A cartridge-type grinding spindle, supported by high-precision angular contact bearings, guarantees optimal radial and axial load performance.

-The taper nose at both ends allows quick and precise mounting of different wheel flanges based on grinding applications.

-The belt-driven spindle system eliminates residual motor vibrations, ensuring stability and longevity.

-The T-480 allows worktable swiveling up to 90° for versatile grinding angles.

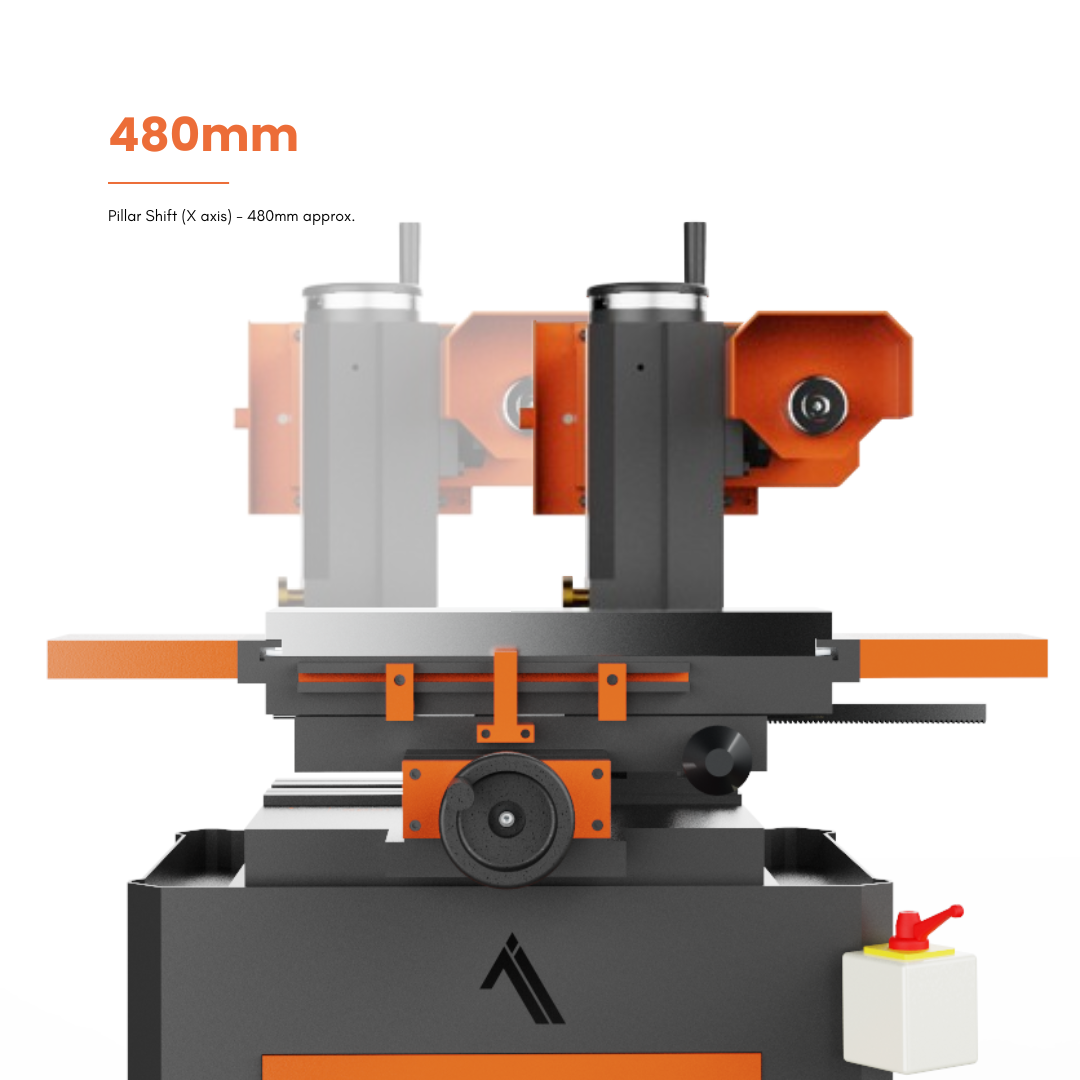

-Pillar shifting across 480mm for optimal tool positioning.

-360° pillar rotation for complete flexibility.

-Tilting spindle head (+/- 15°) for precision grinding (optional feature).

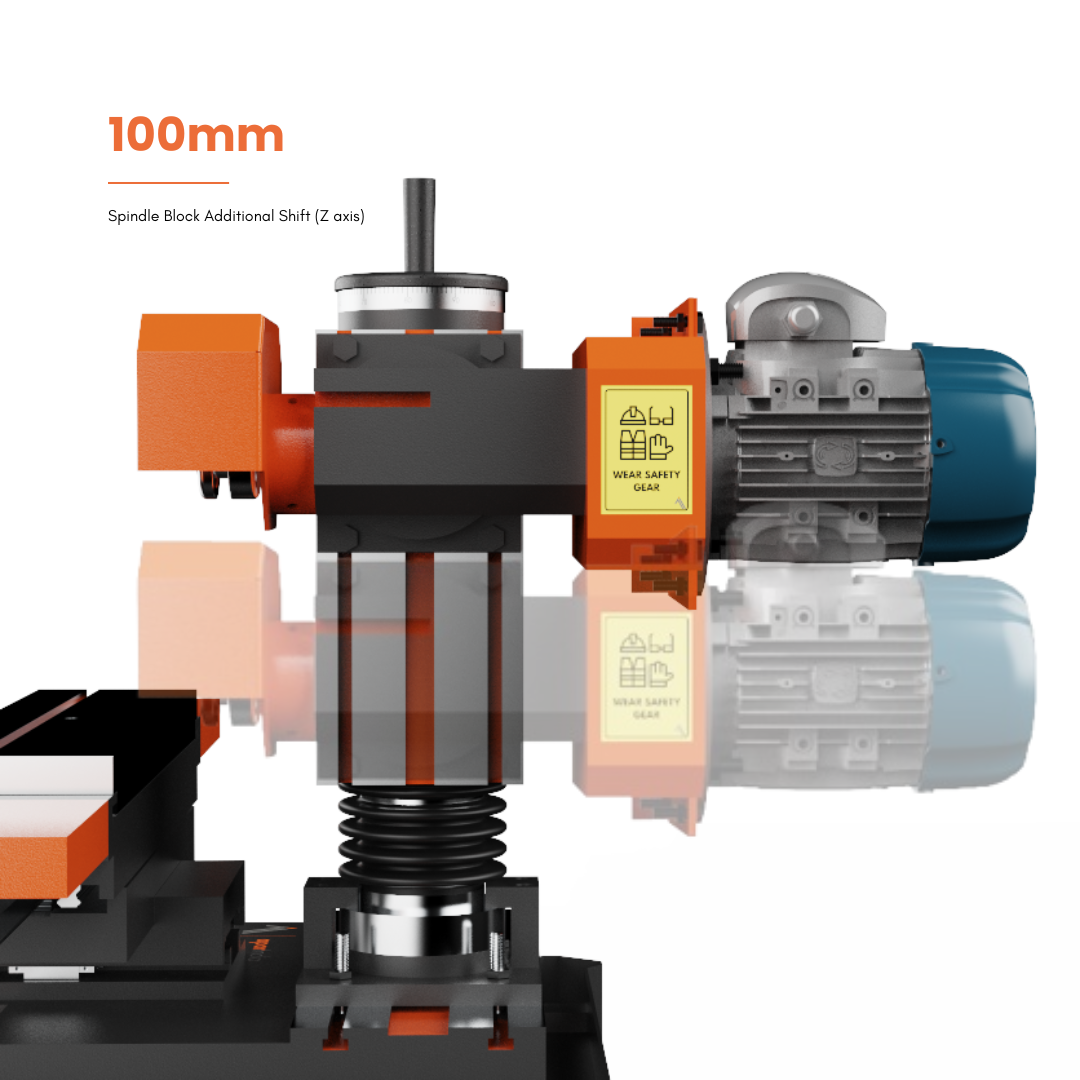

-Spindle block movement for fine-tuned control.

The End Result: Sharpening Made Simple & Effective

With the T-480 Tool & Cutter Grinder, you gain more than just a grinding machine—you gain a cost-effective, high-precision tool sharpening solution. Say goodbye to inconsistent grinds and frequent tool replacements. Instead, extend the life of your cutting tools, maintain peak performance, and boost productivity.

Built for Professionals, Backed by Quality

Manufactured by APAR India Machines, the T-480 is mounted on a rugged steel cabinet with storage compartments and comes with a range of user-friendly attachments for re-grinding and manufacturing standard or specialized tools. Designed to meet IS 3080 quality standards, it is the perfect solution for workshops, tool rooms, and industrial applications.

If you’re looking for a tool and cutter grinding machine that delivers precision, efficiency, and durability, the T-480 is your ultimate companion in tool sharpening and grinding. Upgrade today and experience seamless, high-accuracy grinding like never before.

Share

About T-480

Collapsible content

Application

Technical Specifications

- Max. length between standard centres - 325mm

- Max. length between extended centres - 500mm

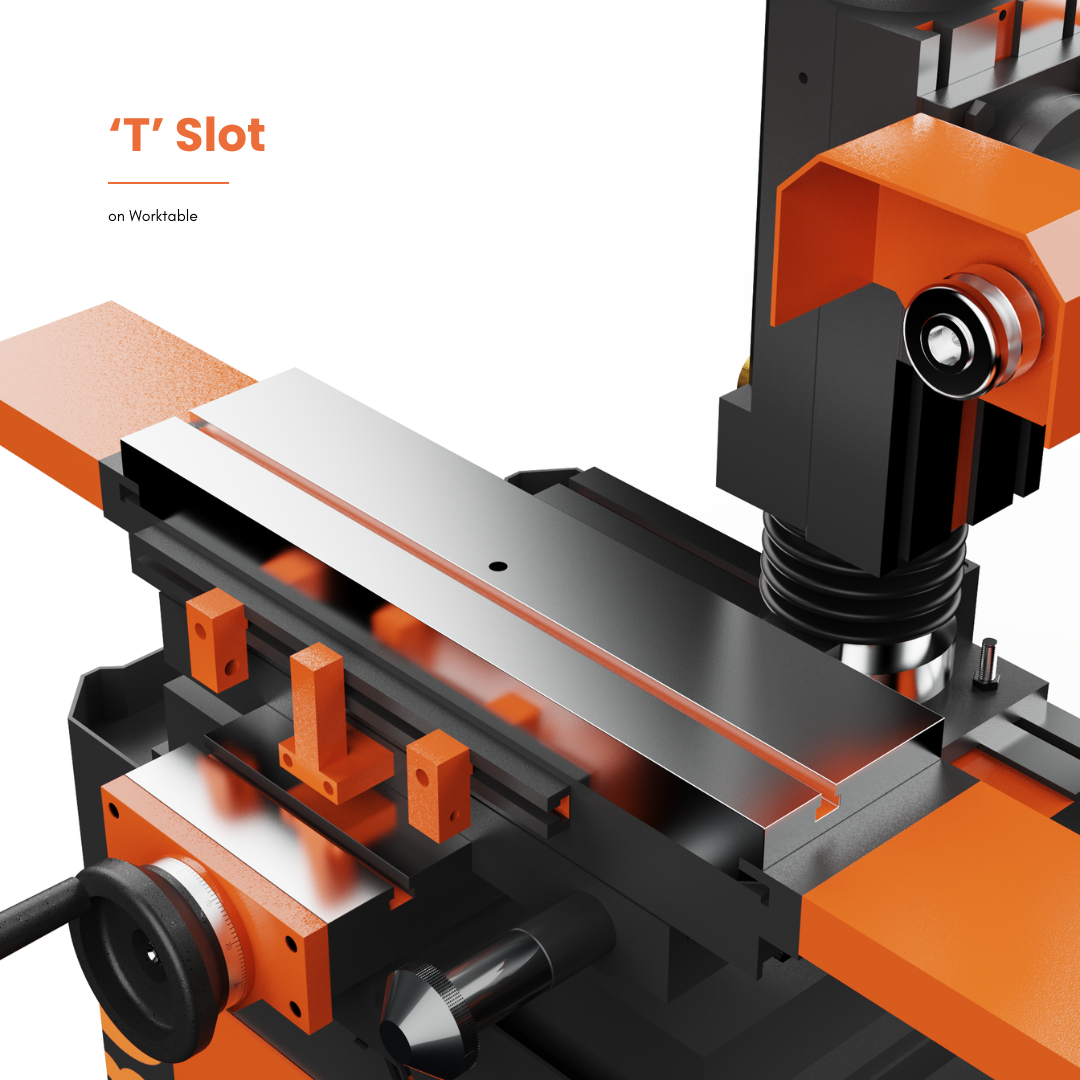

- Surface of worktable - 500mm X 130mm

- Cross traverse - 125mm

- Longitudnal traverse - 275mm

- Vertical traverse - 120mm

- Spindle vertical shifting area by double slide (optional) - 100mm area

- Pillar shifting range on rear surface - 480mm approx.

- Swivel range of top worktable - 90° each side

- Least count of X & Y graduations - 0.01mm / 0.02mm

- Grinding spindle speed - 3600 RPM

- Grinding spindle speed (optional AC drive) - N.A.

- Grinding motor - 0.5 HP, 3 Phase

- C.D. of 'T' slots on worktable - N.A.

- Head swivel range (for tilting head model) - 15° each side

- Swivel range of head pillar - 360°

- Floor area covered - 575 X 625 mm

- Net weight (approx.) - 350 Kgs.

- Dimn. of wooden packaging case (H X W X T) - 1520 X 900 X 720

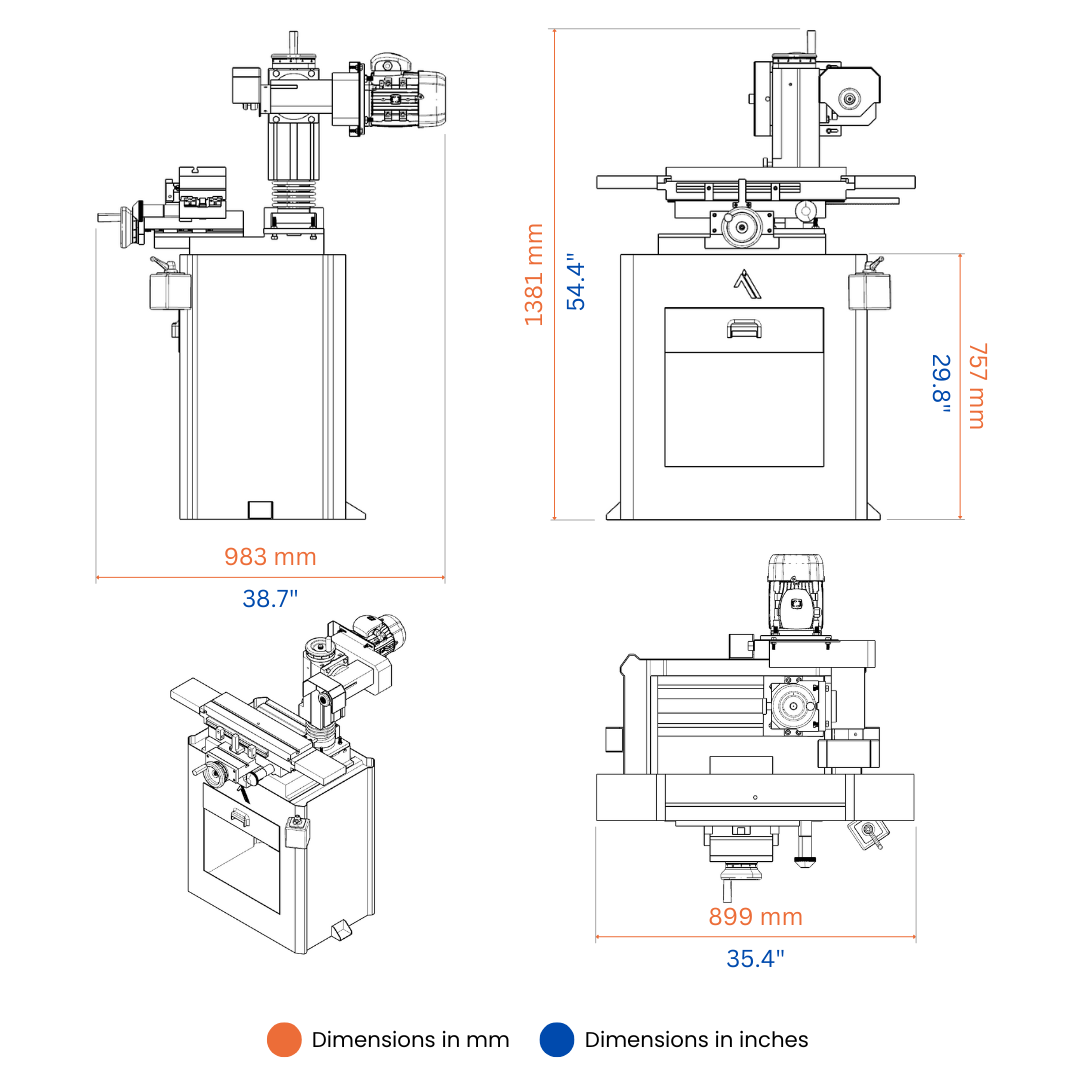

Dimensions

- LxBxH - 1520mm x 900mm x 720mm (approx.)

Shipping

- Delivery between 4-6 weeks after confirmation of order.

Warranty

- 1 year against all mechanical parts