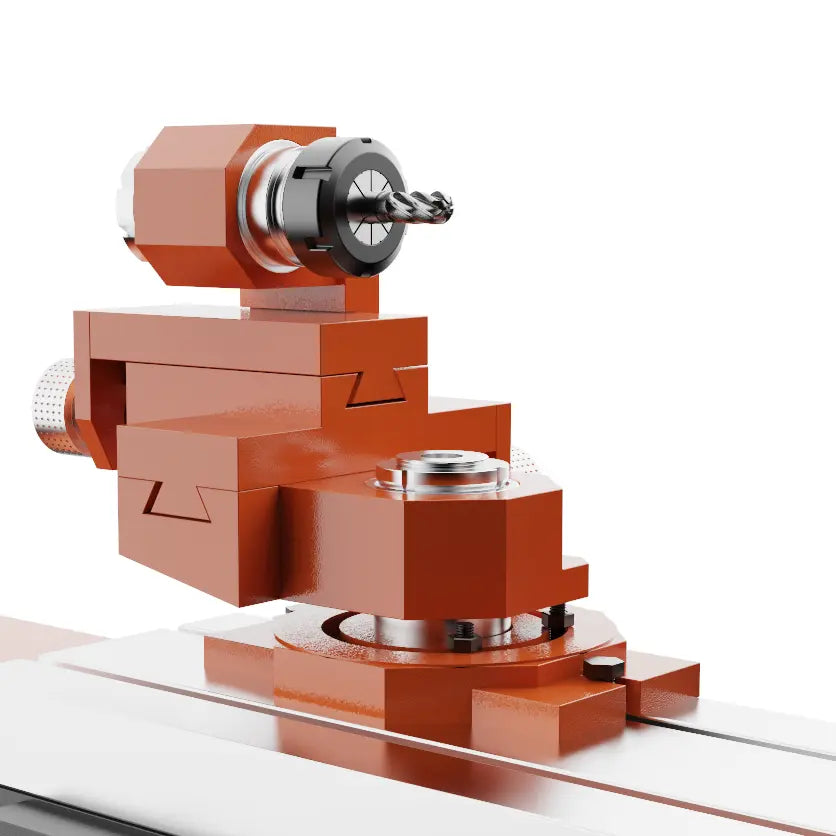

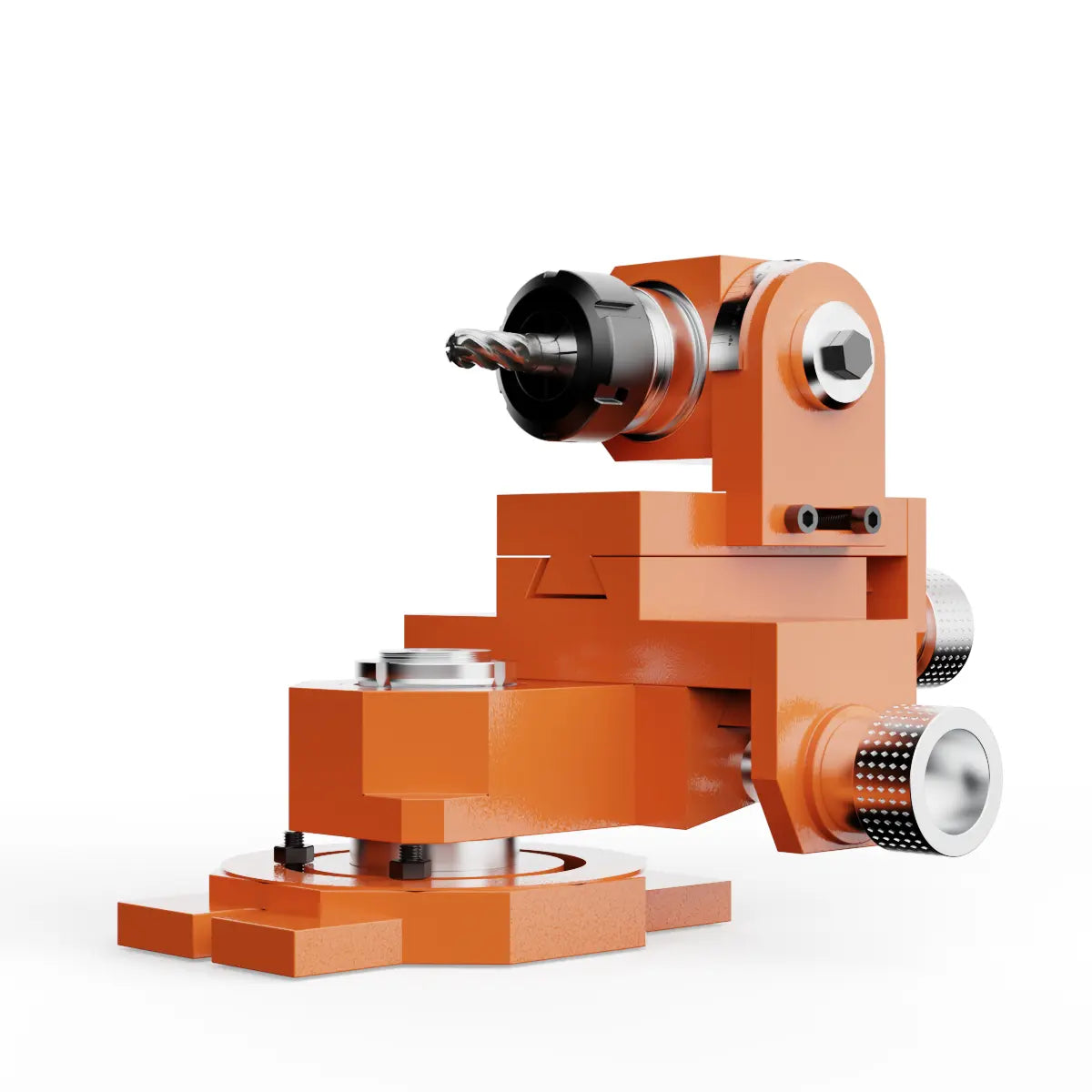

Ball Nose & Radius Grinding Attachment

Ball Nose & Radius Grinding Attachment

Couldn't load pickup availability

In the world of precision machining, achieving flawless curves and sharp radii is a challenge that toolmakers and manufacturers constantly face. Whether it's for carbide or HSS rods, improper grinding often leads to inaccurate profiles, tool inefficiencies, and high material wastage.

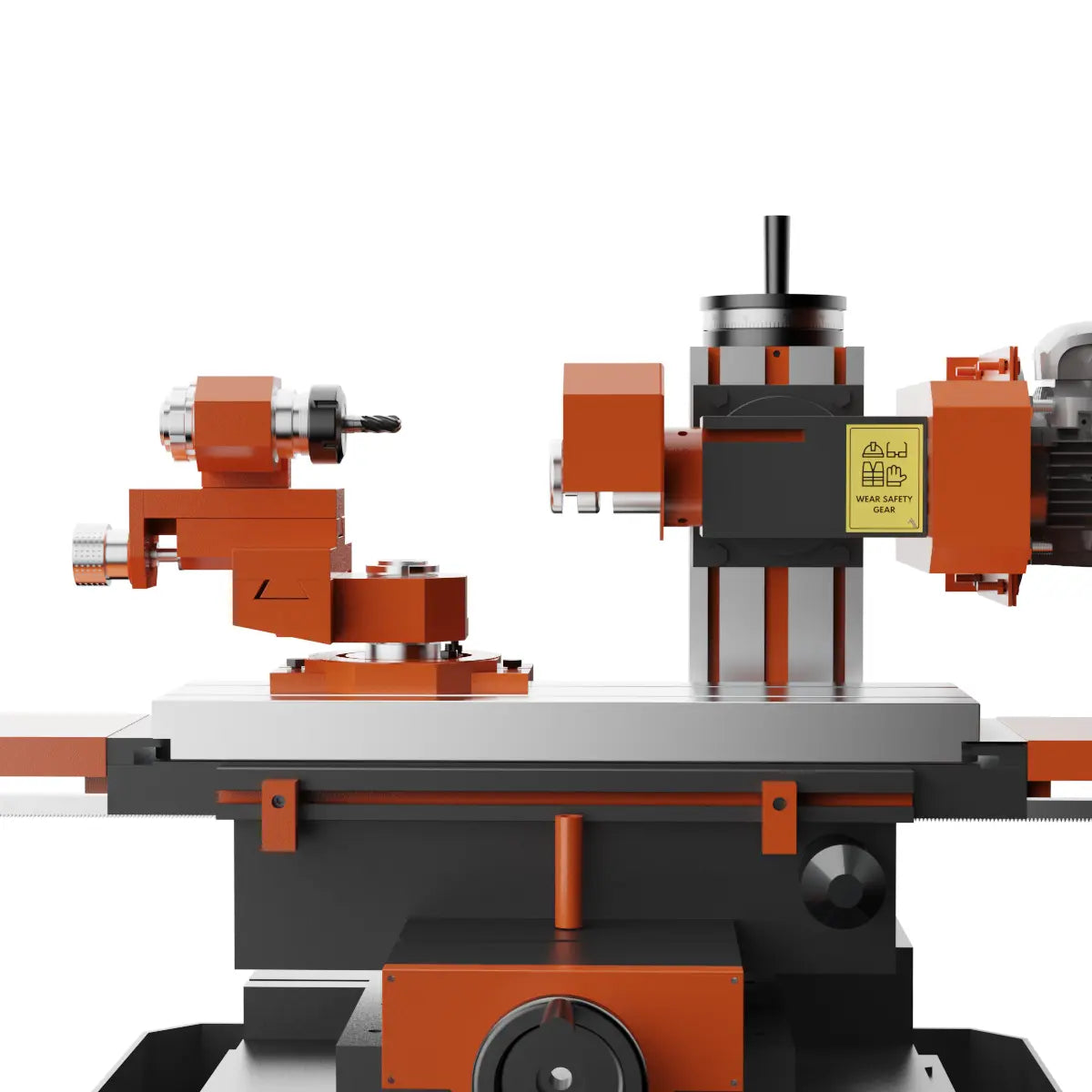

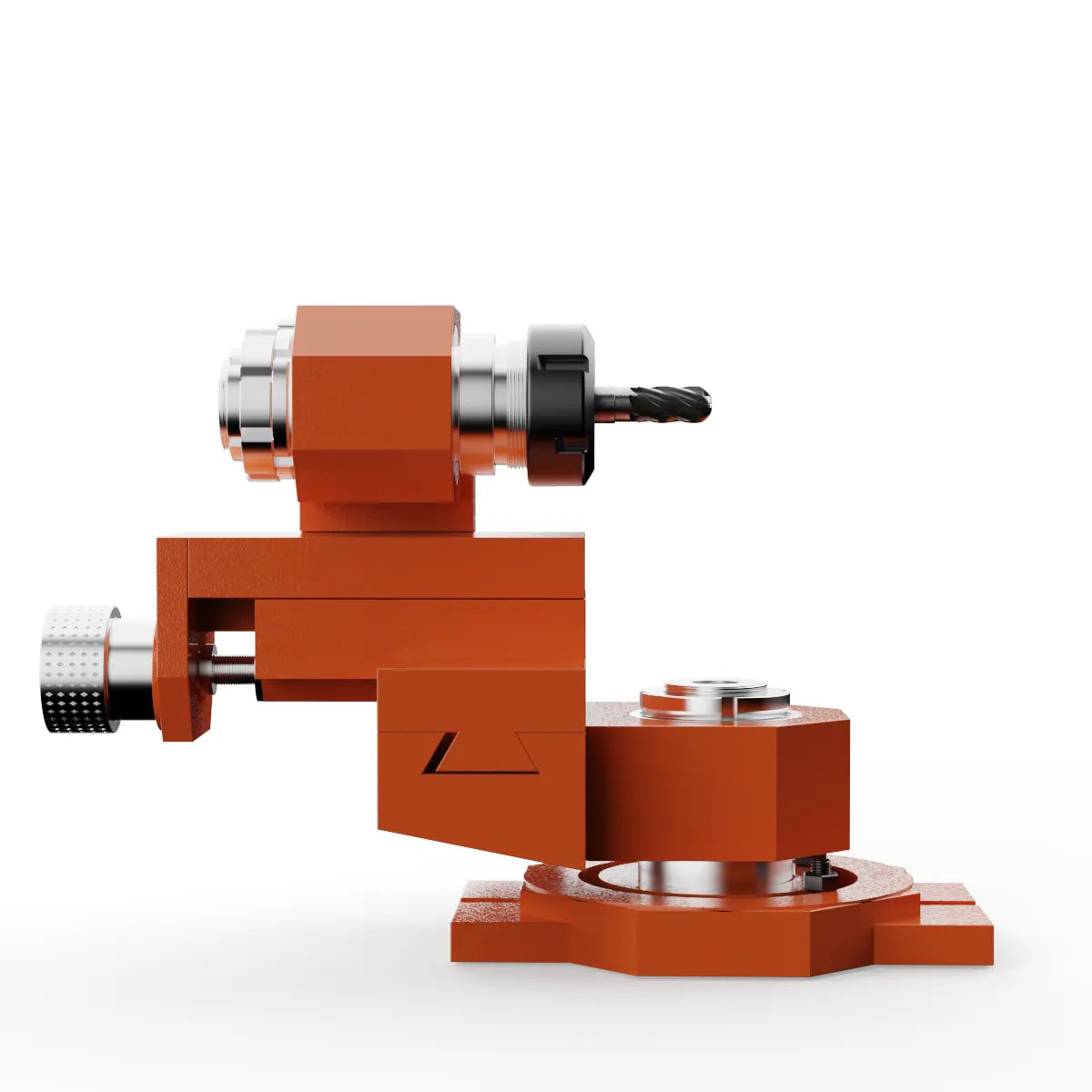

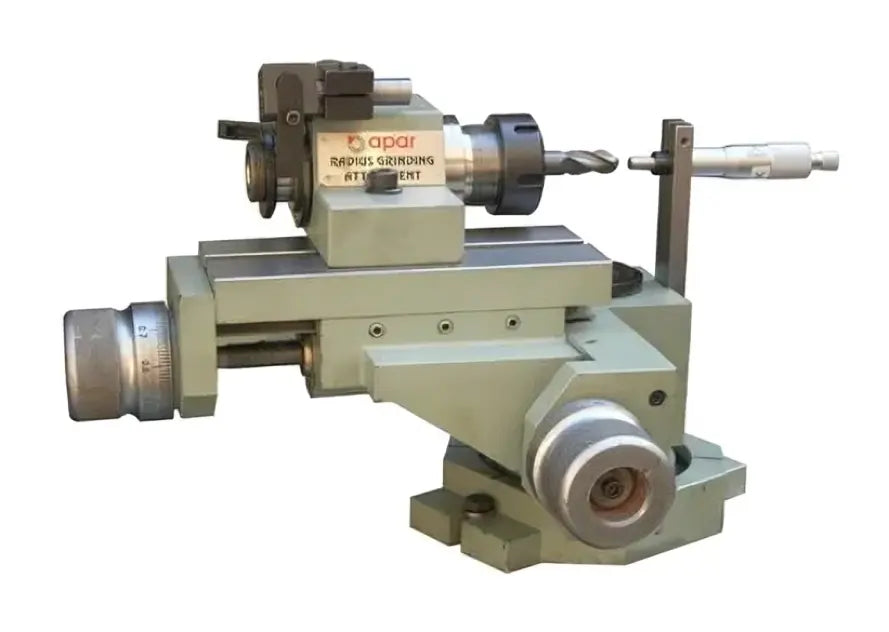

At APAR India, we understand the importance of precise tool shaping for performance-driven industries. That’s why we bring you the Ball Nose & Radius Grinding Attachment, a high-precision accessory designed to integrate seamlessly with your Tool and Cutter Grinding Machines, ensuring perfectly ground ball noses, radii, and complex curves with unmatched accuracy.

This attachment is built to eliminate manual errors, enhance grinding efficiency, and deliver consistent, high-quality results—making it an essential tool for manufacturers, tool rooms, and workshops.

The Problem: Inconsistent Tool Grinding & Wasted Resources

Imagine a toolmaker working on ball nose end mills and carbide blanks. Without precise grinding capabilities, their tools often suffer from:

-Uneven radii, affecting cutting efficiency

-Poor tool life, leading to frequent replacements

-Higher rejection rates, increasing costs

-Time-consuming manual adjustments, reducing productivity

These inefficiencies lead to inconsistent tool performance and unnecessary material wastage.

The Solution: APAR India Ball Nose & Radius Grinding Attachment

Designed for precision, efficiency, and versatility, this attachment allows your Grinding Machines to perform:

-O.D. (Outer Diameter) Grinding – Achieve perfect cylindrical shapes with high accuracy

-Step Grinding – Create precise step profiles for specialized cutting tools

-Centre-point Grinding – Maintain exact alignment for drill and cutting tools

-Taper Point Grinding – Grind seamless tapers for sharp and effective cutting edges

-Face Grinding – Achieve smooth and uniform end surfaces

-Parting – Ensure precise cuts for optimal tool formation

-Diamond-wheel Redressing – Keep grinding wheels in top condition for extended tool life

With this attachment, you can grind ball nose end mills, form cutters, and radius profiles with absolute precision, ensuring every tool performs optimally.

Why Choose the APAR India Ball Nose & Radius Grinding Attachment?

Seamless Integration – Easily attaches to your Tool and Cutter Grinding Machines without complex modifications

Consistent Accuracy – Eliminates manual errors, ensuring every tool is ground to exact specifications

Enhanced Productivity – Reduces setup time, enabling faster grinding cycles

Versatile Applications – Handles carbide, HSS rods, and a variety of cutting tools

Longer Tool Life – Improves sharpness, durability, and efficiency of cutting tools

Real-World Benefits – A Success Story

A leading tool manufacturer struggled with inconsistent ball nose grinding, causing frequent tool rejections and production delays. After adopting the APAR India Ball Nose & Radius Grinding Attachment, they experienced:

- 68% reduction in tool rejection rates

- Improved cutting performance with precise radius grinding

- Increased tool life by 46%, reducing replacement costs

- Higher production efficiency with faster grinding setups

With this attachment, they transformed their Grinding Machines into high-precision tool-sharpening systems, enhancing both product quality and operational efficiency.

Upgrade Your Grinding Process Today

Stop struggling with manual errors and inefficient grinding. Enhance your Tool and Cutter Grinding Machines with the APAR India Ball Nose & Radius Grinding Attachment and experience precision like never before.

Contact us today to see how this attachment can revolutionize your machining process.

APAR India – Innovating Precision, Maximizing Performance.

Share

about ball nose & radius grinding attachment

Collapsible content

Applications

- Blank making of Carbide / HSS rods including O.D. Grinding, Centre-point Grinding, Step Grinding

- O.D. Grinding

- Step Grinding

- Taper Point Grinding

- Parting

- Face Grinding

- Diamond-wheel Redressing

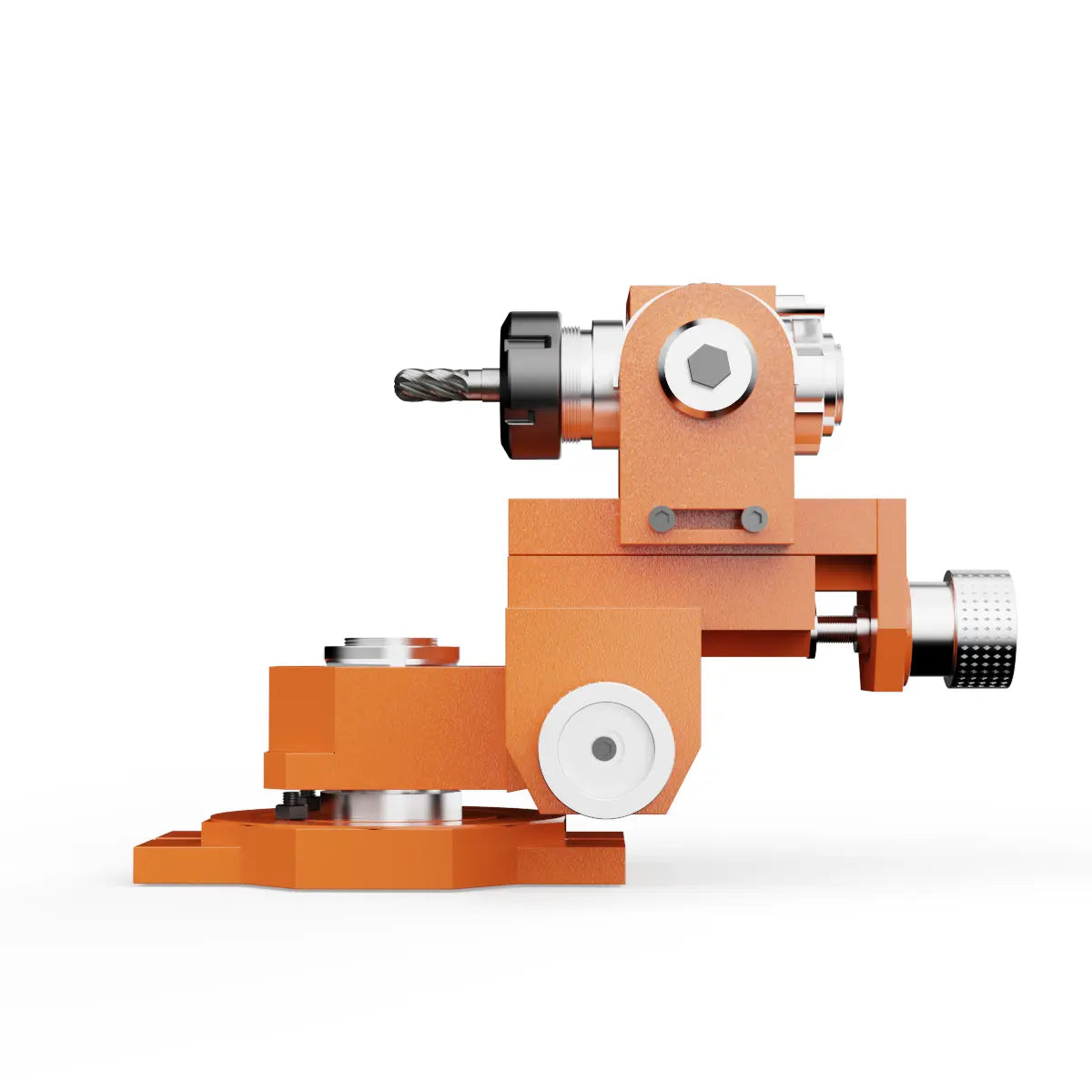

Technical Specifications

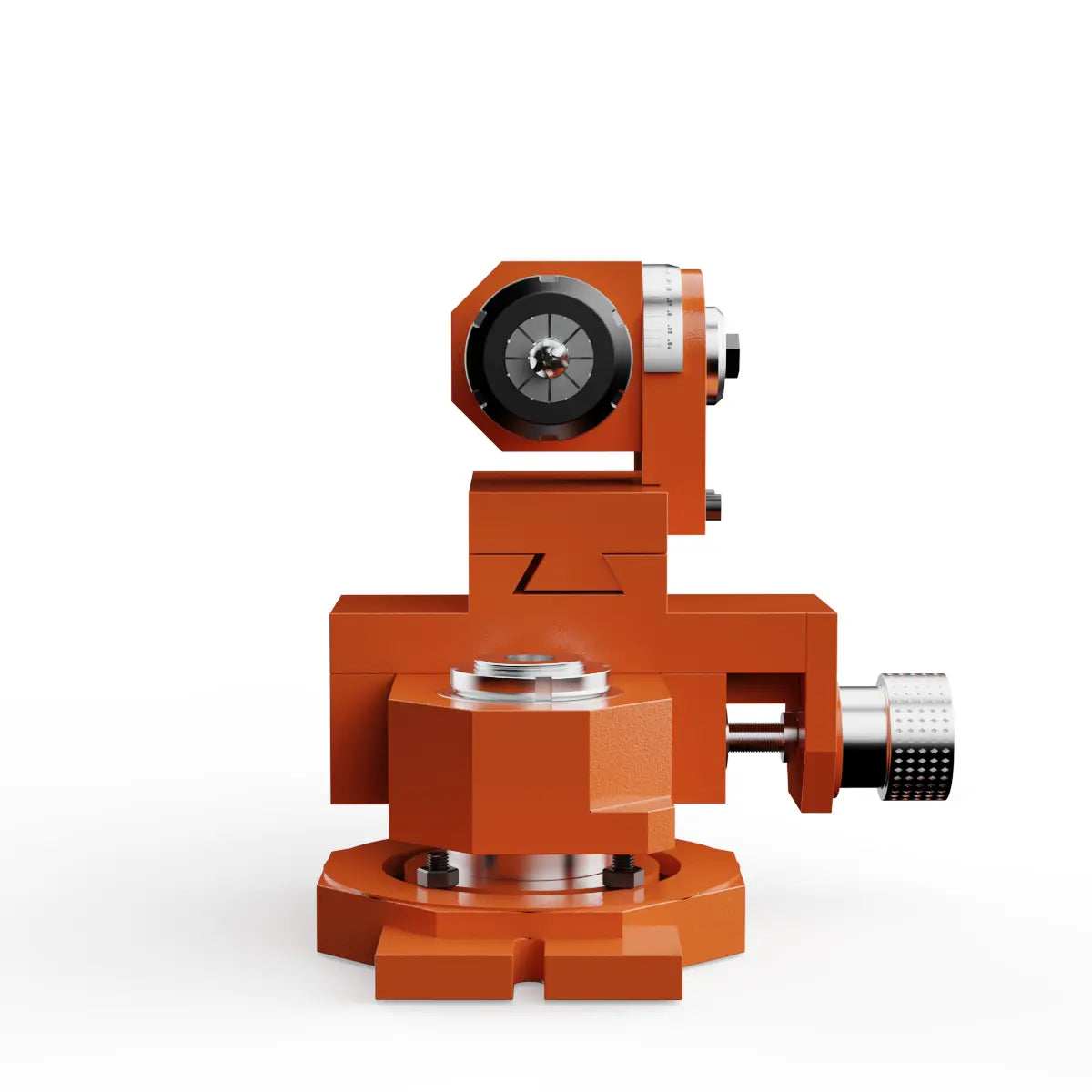

- Centre Height - 112mm (approx.)

- 360° Body Swivel (with step-less locking)

- 350RPM - Standard Spindle RPM with Optional VFD compatibility

- Compatible with chuck

- Belt adjustment system

- Sealed & Dustproof bearings

- Spindle runout - under 10 microns

- Adjustable guide pins

- Weight - 24.00 Kgs (approx.)

Dimensions

- LxBxH - 451mm x 210mm x 375mm (approx.)

Delivery

- Delivery between 1-2 weeks after confirmation of order

Warranty

- 1 year against all mechanical parts