T-401 Tool and Cutter Grinding Machine

T-401 Tool and Cutter Grinding Machine

Couldn't load pickup availability

The T-401 Manual Tool and Cutter Grinding Machine is the most compact and entry-level model in the trusted T-series lineup. Designed with simplicity in mind, this grinding machine is ideal for environments where space, cost, and basic functionality matter most. From training centres to small-scale workshops, the T-401 solves... Read More

The T-401 Manual Tool and Cutter Grinding Machine is the most compact and entry-level model in the trusted T-series lineup. Designed with simplicity in mind, this grinding machine is ideal for environments where space, cost, and basic functionality matter most. From training centres to small-scale workshops, the T-401 solves a critical gap in many setups—how to sharpen tools efficiently without the cost or complexity of heavy-duty manufacturing equipment.

This tool grinding machine is perfect for those who need a reliable way to maintain sharp cutting tools in low-volume scenarios. In educational institutions like ITIs, vocational training centres, and polytechnic colleges, the T-401 functions as a foundational machine tool, helping students understand grinding operations through real-world practice. As a tool cutter grinder machine, it allows easy resharpening of end mills, small drill bits, lathe tools, single-point cutting tools and ball nose end mills which are essential in teaching and light-duty machining environments.

In small factories or internal maintenance shops, the T-401 offers on-the-spot tool correction—reducing machine downtime and improving overall productivity. It supports basic grinding of clearance angles, relief angles, and tool nose angles, making it a handy universal cutter grinder for workshops that don’t require CNC precision but still demand accuracy.

For hobbyists, model engineers, and micro-workshops, the T-401 is a game-changer. Its compact size fits on any bench, yet it functions as a full-fledged tool grinding machine for day-to-day reshaping tasks. It's a budget-friendly option for makers who need practical machine tools without investing in large-scale manufacturing equipment.

If you're looking for a compact, affordable, and dependable tool cutter grinder machine that fits seamlessly into small setups or educational environments, the T-401 is your go-to grinding machine—simple to operate, versatile in use, and built to deliver reliable results.

Applications

Applications

The T-401 Manual Tool and Cutter Grinding Machine is the smallest and most basic model in the T-series lineup. It’s designed primarily for very light-duty applications, educational use, and simple resharpening tasks in environments where compactness and cost-effectiveness are key.

Here are the main applications of the T-401:

🔧 1. Basic Resharpening Tasks

- Small drill bits

- Simple lathe tools

- Single-point cutting tools

- Small HSS tools (not suitable for carbide or heavy-duty tools)

- Ideal for basic reshaping and touch-up sharpening.

🛠️ 2. Educational and Training Institutes

- Industrial Training Institutes (ITI's)

- Polytechnic Colleges

- Vocational Training Centers

🧰 3. Small Maintenance Shops and Internal Workshops

- Used in internal maintenance departments of small factories.

- Helps in quick sharpening of basic tools used in production or repair lines.

- Keeps downtime low for small machine tools.

🪚 4. Simple Angle Grinding

- Clearance angles

- Relief angles

- Tool nose angles

- Supports , but limited precision compared to higher models.

🏠 5.Hobbyist and Micro-Scale Workshops

- Handy for DIY users, model engineers, or small prototyping setups.

- Compact design makes it suitable for bench-top use.

Technical Specifications

Technical Specifications

- Surface of worktable - 455mm X 130mm

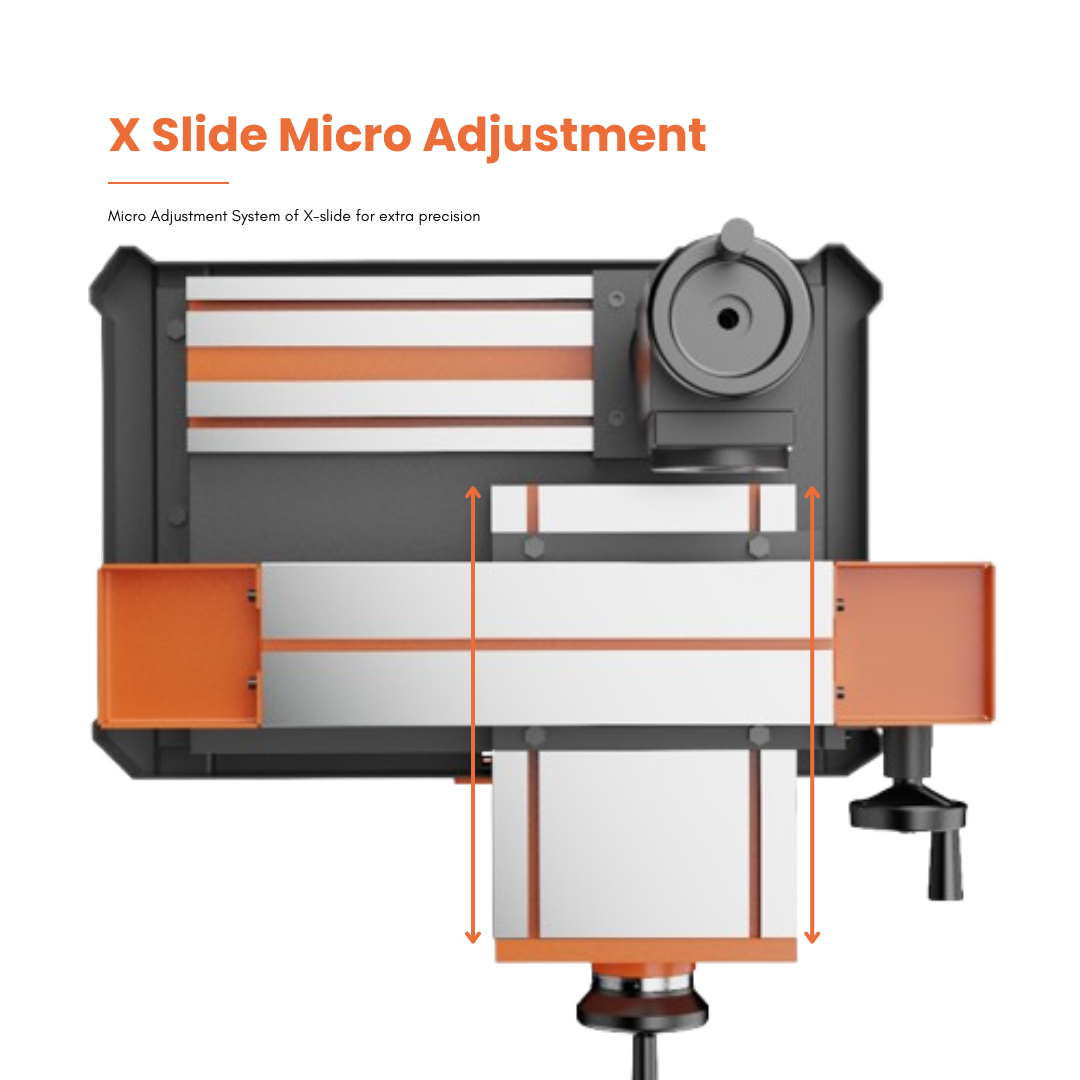

- Cross traverse - 125mm

- Longitudnal traverse - 300mm

- Vertical traverse - 175mm

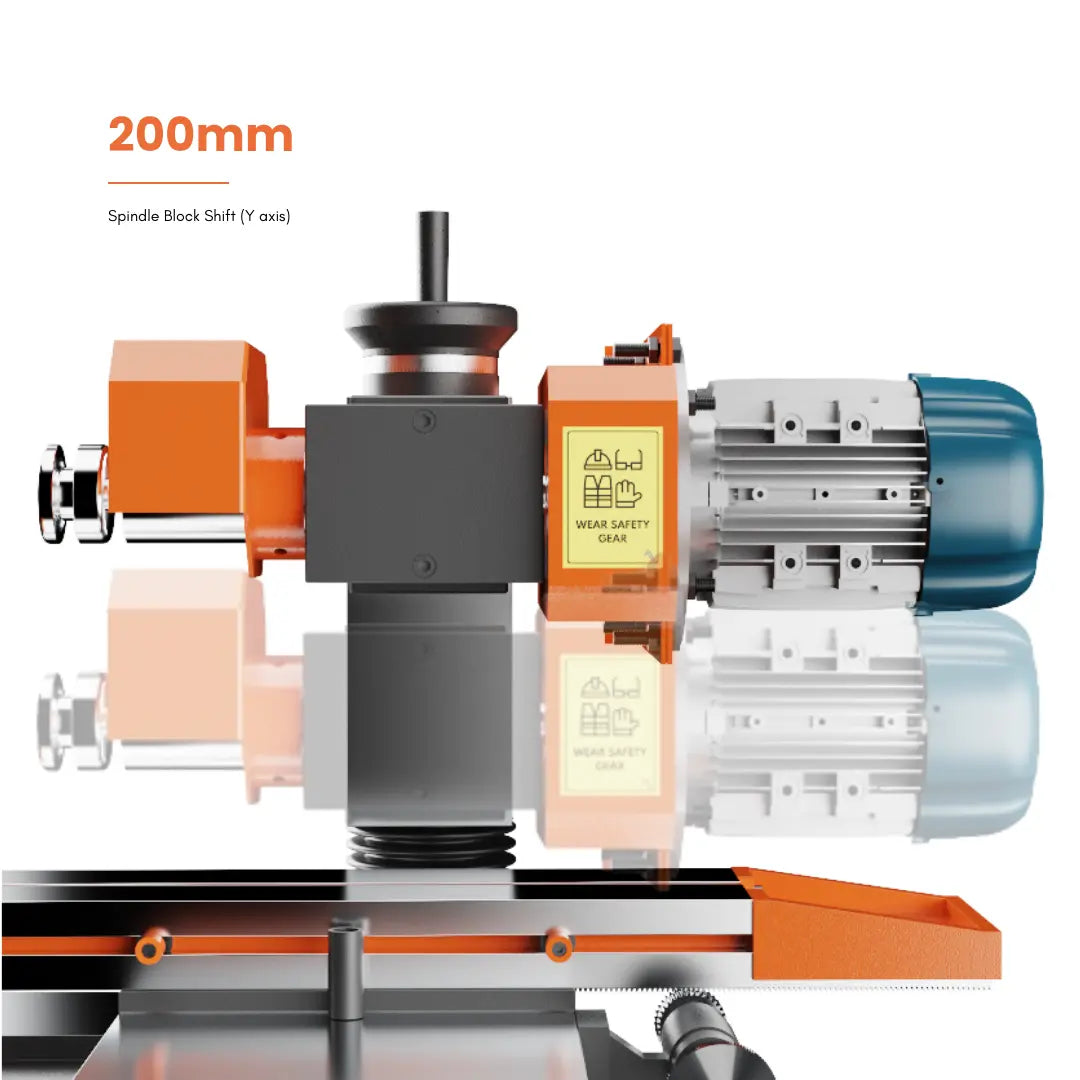

- Spindle vertical shifting area by double slide (optional) - 200mm area

- Pillar shifting range on rear surface - 400mm approx.

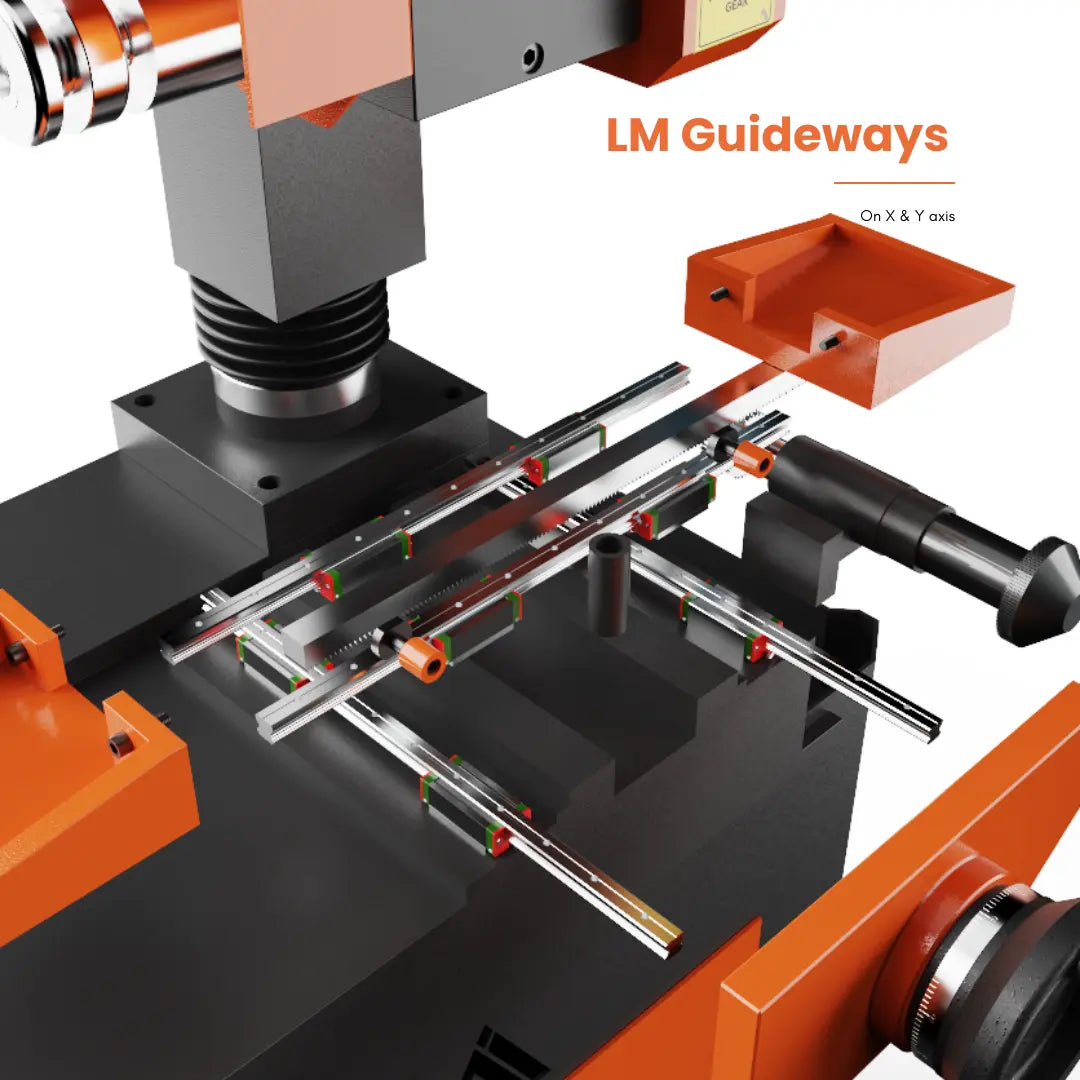

- Least count of X & Y graduations - 0.06mm

- Grinding spindle speed - 3600 RPM

- Grinding spindle speed (optional AC drive) - 2500 – 6000 RPM

- Grinding motor - 0.3 HP, 3 Phase

- C.D. of 'T' slot on worktable - 90 mm

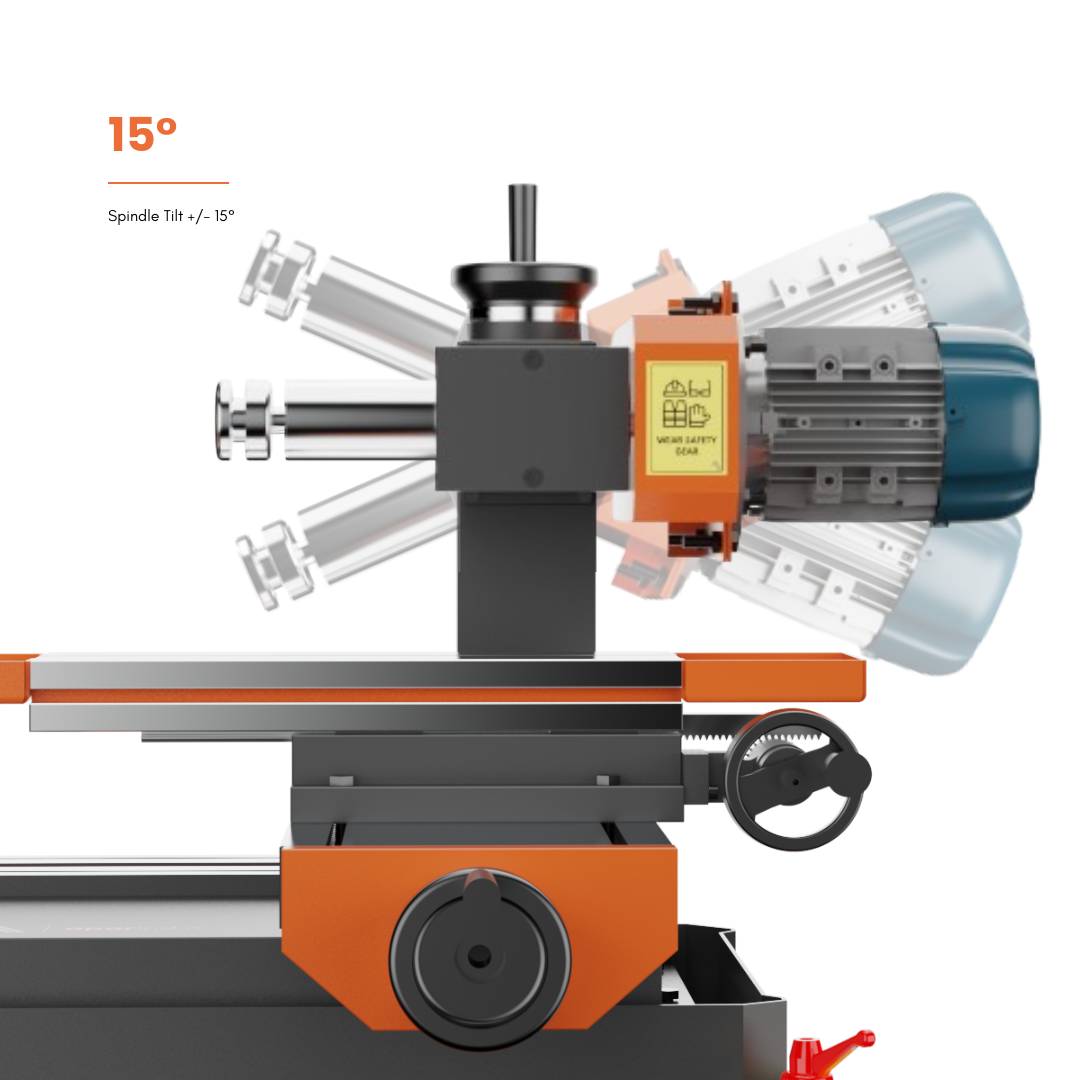

- Head swivel range (for tilting head model) - 15° each side

- Swivel range of head pillar - 360°

- Floor area covered - 467 X 675 mm

- Net weight (approx.) - 150 Kgs.

- Dimn. of wooden packaging case (H X W X T) - 1400 X 700 X 720

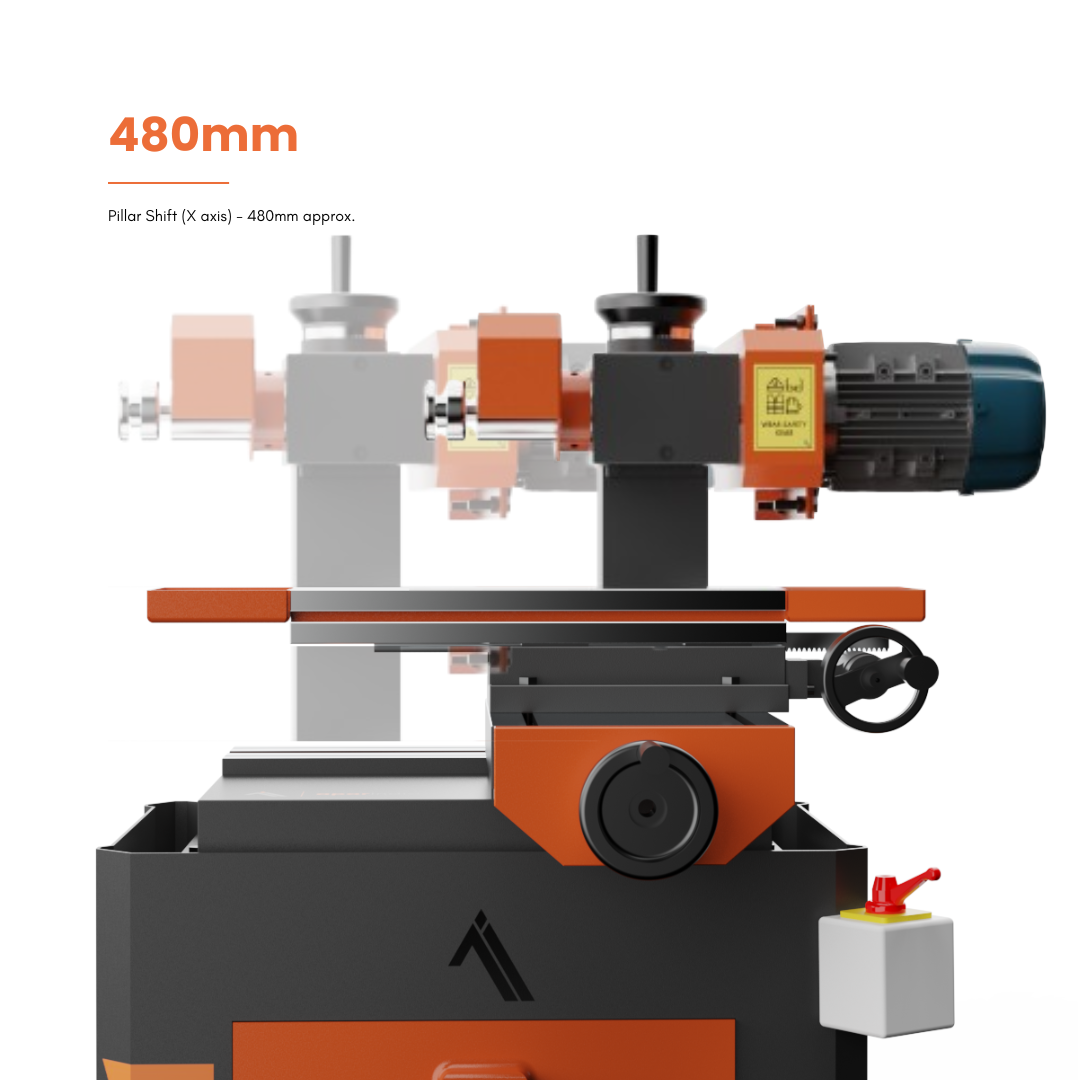

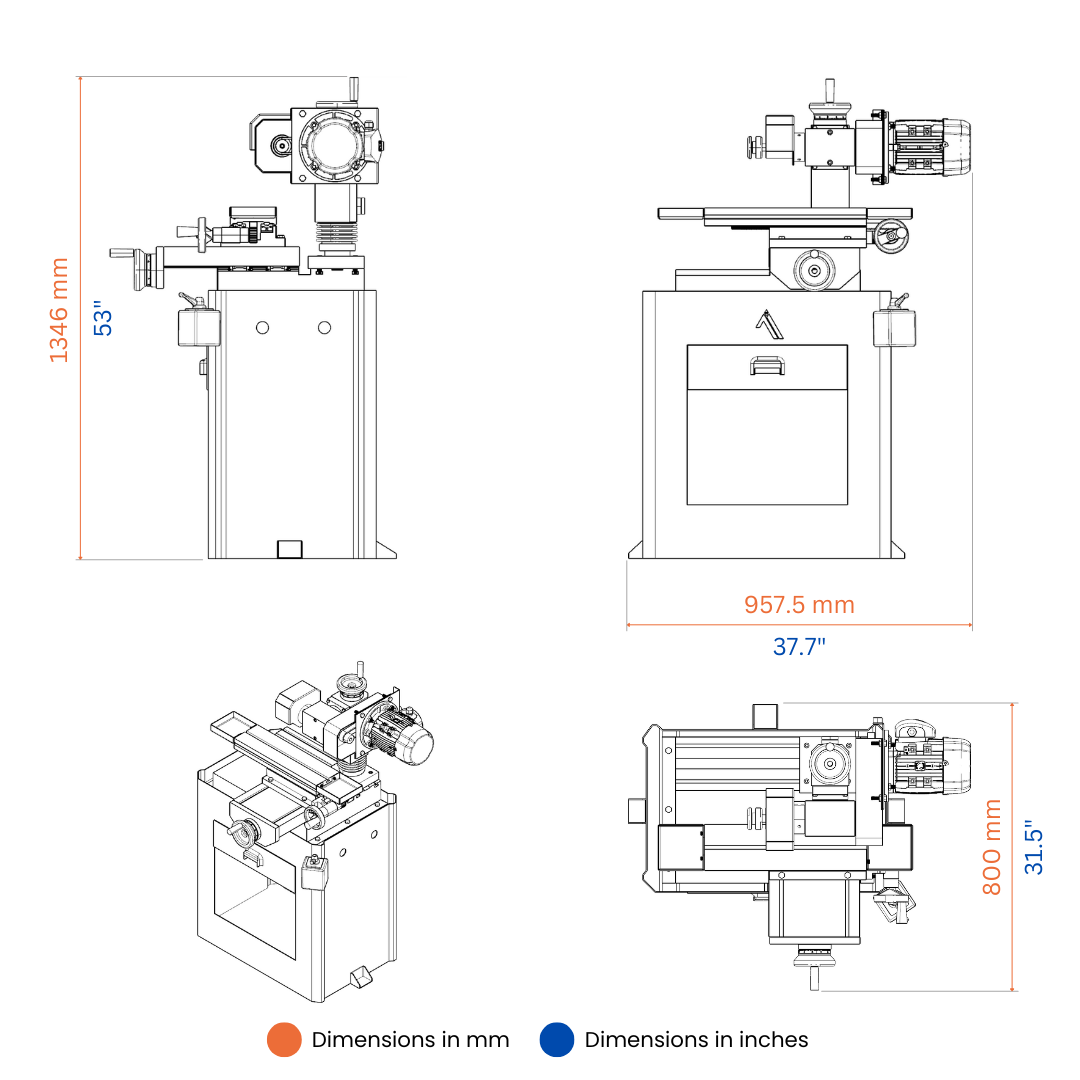

Dimensions

Dimensions

- LxBxH - 467mm x 675mm x 700mm (approx.)

Shipping

Shipping

- 4-6 weeks after confirmation of order

Warranty

Warranty

- 1 year against all mechanical parts

Share

FREquently asked questions

Collapsible content

Why Trust Apar?

The T-401 Manual Tool and Cutter Grinding Machine is the smallest and most basic model in the T-series lineup. It’s designed primarily for very light-duty applications, educational use, and simple resharpening tasks in environments where compactness and cost-effectiveness are key.

Here are the main applications of the T-401:

🔧 1. Basic Resharpening Tasks

- Small drill bits

- Simple lathe tools

- Single-point cutting tools

- Small HSS tools (not suitable for carbide or heavy-duty tools)

- Ideal for basic reshaping and touch-up sharpening.

🛠️ 2. Educational and Training Institutes

- Industrial Training Institutes (ITI's)

- Polytechnic Colleges

- Vocational Training Centers

🧰 3. Small Maintenance Shops and Internal Workshops

- Used in internal maintenance departments of small factories.

- Helps in quick sharpening of basic tools used in production or repair lines.

- Keeps downtime low for small machine tools.

🪚 4. Simple Angle Grinding

- Clearance angles

- Relief angles

- Tool nose angles

- Supports , but limited precision compared to higher models.

🏠 5.Hobbyist and Micro-Scale Workshops

- Handy for DIY users, model engineers, or small prototyping setups.

- Compact design makes it suitable for bench-top use.

Is the T-401 suitable for tool rooms in the automotive industry?

Yes. Automotive tool rooms rely on the T-401 for precise resharpening of carbide and HSS tools used in dies, molds, and fixture production. Its repeatability and accuracy help maintain tooling standards critical to automotive manufacturing.

Can this machine handle the demands of high-mix, low-volume job shops?

Absolutely. The T-401’s versatility and quick setup make it perfect for job shops handling different tool geometries and sizes. It adapts easily to varied applications, reducing downtime and increasing shop efficiency.

Can the T-401 be integrated into an existing maintenance workflow in an engineering plant?

Many general engineering companies use the T-401 in their in-house tool maintenance departments to reduce downtime and ensure sharp tools are always ready for production.

Is the machine reliable for round-the-clock usage in production environments?

Yes. Its industrial-grade construction and thermal stability make it dependable for continuous operation in high-output environments with minimal breakdowns.

What all applications can i do on this machine?

Key Application Areas:

VMC Tool Resharpening: End mills (straight and ball-nose), drills, taps, custom tools etc.

Woodworking Tool Maintenance: Router bits, profiling tools and planar knives

Surgical Tool Grinding: Orthopedic tools, blades, and microsurgical components

Gundrill Regrinding: Reconditioning of deep-hole drilling tools

Engraving & Micro-Tooling: Precision reshaping of fine HSS and carbide bits

Does the machine comply with international electrical and safety standards?

Yes. The T-401 can be customized for different voltage and frequency requirements (e.g., 220V/440V, 50Hz/60Hz) and follows standard industrial safety protocols suitable for global markets.

Do you offer special pricing for bulk orders or dealers?

Yes, we offer dealer pricing, volume-based discounts, and special commercial terms for bulk orders. For most machines, including the T-401, there are MOQ for dealer rates. However, we’re flexible for first-time partners or region-specific requirements.

Can we get exclusive dealership rights for a particular region?

Yes, we are open to exclusive dealership agreements based on your sales capacity, after-sales service capabilities, and market presence in the proposed region.