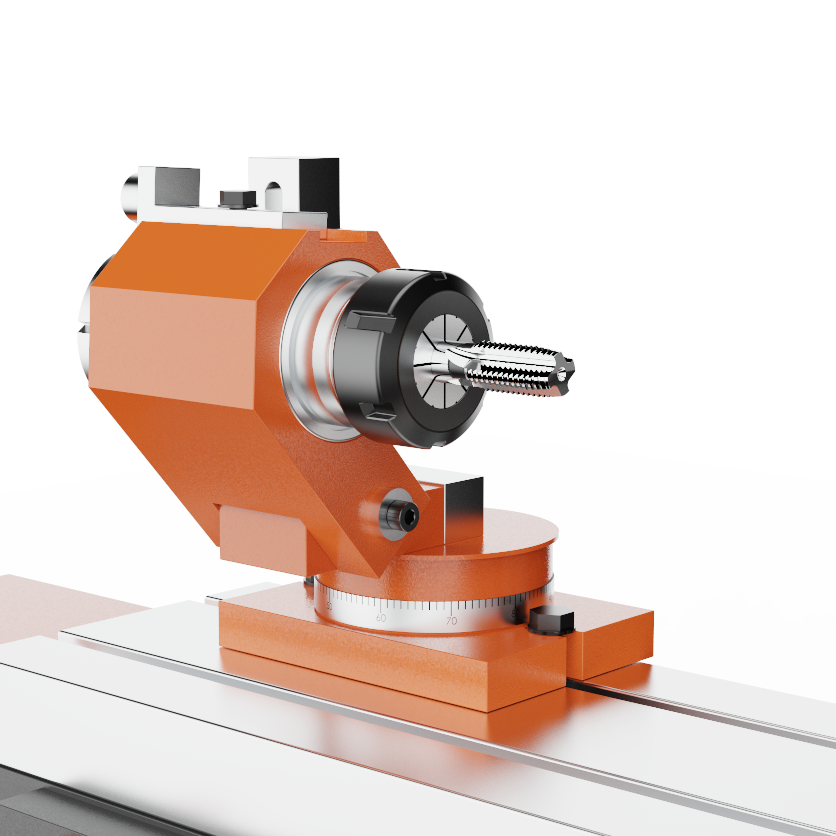

Tap Sharpening Fixture

Tap Sharpening Fixture

Couldn't load pickup availability

Why Tap Sharpening Fixture is Essential in Modern Tool Grinding Operations

In everyday machine shop environments, tap tools lose cutting performance quickly due to continuous use in drilling, tapping, counterboring, and countersinking operations. The common problems faced include chipped tap edges, dull cutting flutes, poor thread finishing, frequent... Read More

Why Tap Sharpening Fixture is Essential in Modern Tool Grinding Operations

In everyday machine shop environments, tap tools lose cutting performance quickly due to continuous use in drilling, tapping, counterboring, and countersinking operations. The common problems faced include chipped tap edges, dull cutting flutes, poor thread finishing, frequent tool replacement, and inconsistent hole threading. Many workshops, especially in small to mid-sized industries, lack a reliable system to restore these tools efficiently.

This is where the tap sharpening grinding fixture becomes a practical and cost-effective solution. Designed to work seamlessly with a standard tap grinding machine or tool cutter grinder, this fixture enables precise and repeatable resharpening of straight and spiral flute taps used in both manual and CNC machining environments. Whether you’re dealing with standard M-taps, fine-pitch taps, or special threading tools, the tap sharpening fixture helps solve critical tool wear issues that often lead to production delays and poor threading accuracy.

Increase Tool Life and Performance with Tap Sharpening Fixture

Without a proper tap sharpening machine, tap tools often get discarded early due to edge wear and flute deformation. By using the tap sharpening grinding fixture, workshops can effectively regrind damaged taps and restore their original geometry. This allows for:

-

Consistent thread cutting across components

-

Reduced tool rejection rate

-

Less downtime on machines during tool changes

-

Significant cost savings on new tap procurement

Even with light to medium-duty milling work on conventional machines or VMC setups, the tap sharpening fixture ensures taps are ready for high-performance output. It eliminates the dependency on third-party grinding services and gives toolrooms full control over sharpening quality and timing.

Applications of Tap Sharpening Fixture in Manufacturing Equipment

The tap sharpening grinding fixture is suitable for:

-

Tool grinding: Quick and accurate resharpening of standard and special taps

-

Milling setups: Where clean, accurate pre-tap holes are crucial for operations

-

Drilling and tapping lines: Where continuous tap use can degrade performance over time

-

Conventional and CNC machines: Compatible with toolrooms using manual grinders or VMCs

-

Educational and technical training institutes: Teaching basic and advanced tap grinding skills

When used with a robust tap grinding machine, this fixture supports high-quality tool maintenance. Even semi-skilled operators can achieve consistent results, avoiding uneven relief angles and incorrect thread forms, which are common with manual sharpening methods.

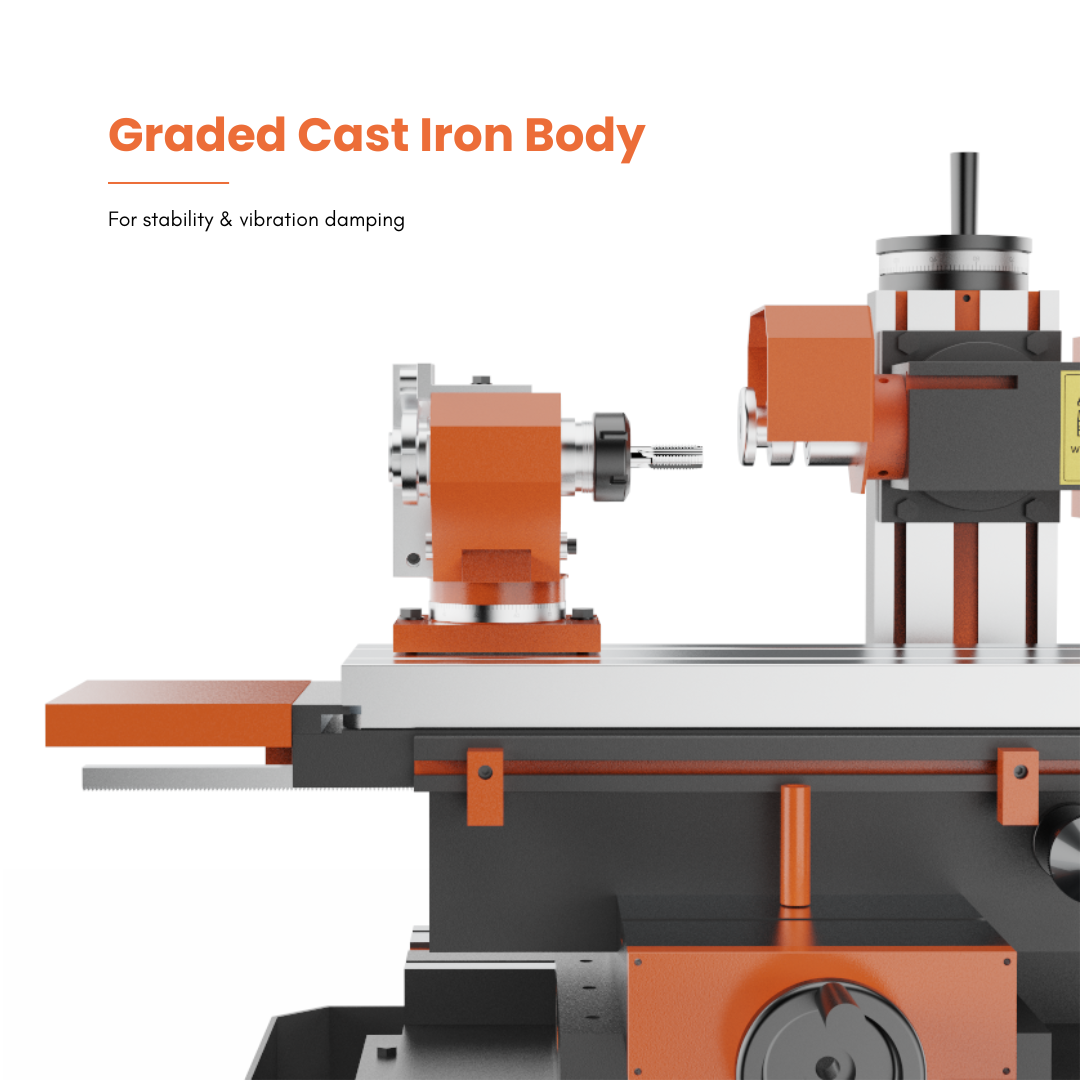

Easy Integration and Long-Term Productivity

Integrating the tap sharpening fixture into your workshop workflow is simple. The fixture mounts easily onto most universal tool and cutter grinders, converting them into specialized tap sharpening machines. It is compact and operator-friendly, making it ideal for internal maintenance departments, job shops, and SMEs in automotive, aerospace, general manufacturing, and fabrication industries.

By incorporating the tap sharpening grinding fixture into your manufacturing equipment line, you eliminate common tool grinding challenges such as poor flute relief, incorrect rake angles, and damaged cutting edges. This results in better machining efficiency, longer tool life, and reduced rejection rates on final components.

Conclusion: Invest in the Right Tap Sharpening Solution

The tap sharpening grinding fixture is more than just an accessory—it’s a productivity-enhancing addition to any toolroom. When paired with a reliable tap sharpening machine, it ensures your taps remain in peak condition without outsourcing or constant tool replacement. This is especially valuable for industries with high usage of tapping tools in operations like drilling, reaming, countersinking, and thread finishing.

If you’re looking for a dependable, precise, and affordable tap resharpening solution, the tap sharpening fixture and tap grinding machine setup offers a complete answer to your tool maintenance needs.

Technical Specification

Technical Specification

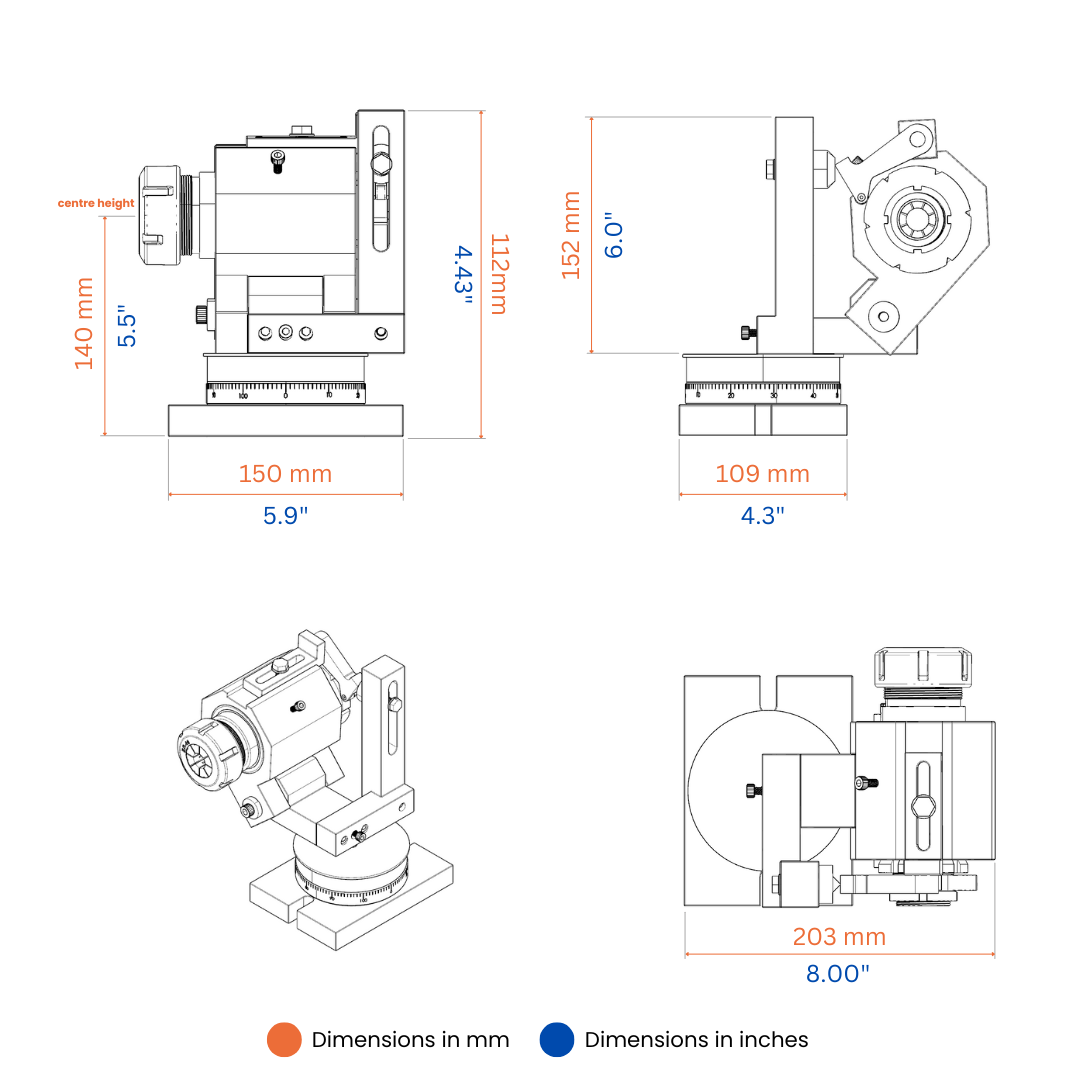

- Centre Height - 104mm (approx.)

- 360° Body Swivel (with step-less locking)

- Sealed & Dustproof bearings

- Spindle runout - under 10 microns

- Spindle locking is done by twin bushes with spring assemby for rigidity & location retention

- Spring loaded indexing assembly with quick change indexing plates

- Adjustable guide pins

- Weight - 10.00 Kgs (approx.)

Dimensions

Dimensions

- LxBxH - 173mm x 124mm x 104mm (approx.)

Shipping

Shipping

- Delivery between 1-2 weeks after confirmation of order.

Warranty

Warranty

- 1 year against all mechanical parts

Share